Photo Gallery

More Soon SEE hydrogenfarmingtv Channel on Youtube

Still under construction

Quis cignissim

Learn More

Tap the power at its source and deliver it to the farm

Hydrogen made with micro hydropower is the fuel

for N2 conversion to Ammonia to Fertilze the fields

Its like fracking the hydropower resource

This a project and certainly a good story about green chemicals. It's about carbon dioxide, and methane and the heroine ammonia. The project starts at the top of the world ...or at the highest elevation in a region country or state. It's a innovative process or plan that offers extra ordinary results to the environment and community it will serve. It is especially well suited to developing country's and areas in need of improved food resources and economic industries. Similar to common processes and development of existing systems operational around the world it point out n overlooked or unrealized opportunity to improve the condition of the environment.

Hydrogen farming is like dairy farming here in Wisconsin, where every day, every month, every year, milk produced on thousands of individual farms in the state is harvested and brought to production as consumable food products.Hydrogen produced by Hydro generators in elevated watersheds can be harvested in the same way our milk in Wisconsin. Raw hydrogen produced by Hydro generators in elevated watersheds can be harvested in the same way our milk in Wisconsin is harvested and brought to the production.The production of ammonia that can be used as fertilizer to provide food in the valleys of the source of the hydrogen. Hydrogen farming can also be compared to the concept of wind farming, where multiple with generators produce significant amounts of electrical energy to be used to power communities. Hydrogen farming can be used to help feed the community, especially in the most developing areas

Storage and transportation of Hydrogen and Ammonia.

The innovation of hydrogen farming that we will show is the all about the the delivery of hydrogen to useful production from untapped sources. Similar to the concept of Fracking now employed by the oil industry, that opens new channels to fuels reserves formerly inaccessible. Like fracking, by the addition of some simple processes, hydro farming can extract significantly more clean energy from what was considered a dry well. It is completely achievable in many ways with currently available technologies. The monetary costs of significant achievement is also achievable and low especially in comparison to that of wind farming. This can also be a significant advantage to poor developing areas of the world. It can offer significant opportunities to ambitious individuals or company's wanting greater profits. The best part of our presentation is that it will perhaps open new pathways for developer and innovators in the field of alternative energy as we consider new ways to store and transport energy..

So let's talk about that dry well, the dry well of Hydro production in the world. The problem really stems from the fact that only the bottom 10th of the hydrogen potential is utilized. Hydro power has been harvested for centuries. People think it's all used up. It's all used up because conventional Hydro requires a dam. People think the only way we can get more Hydro is with bigger and better dams. This is very true and in most cases it is a stopper in bottle of development and even consideration by most all energy developers. The most important thing about hydro farming is it does not require dams therefore it is environmentally friendly and it has 10 times the potential of all the hydro power of the planet today. Ten times is likely conservative could be 100s , or like if we could frack all the oil wells we have ever drilled how much oil could we get. Well, I think a lot. Fracking will continue to produce more and cheaper gas and oil so let's counter it with more and cheaper Hydro farm fuels for the future. This is how we do it.

Snowmelt and seasonal rains run down the mountail to the fertile valleys below. Harvisting power in the mountains is almost non- existant but highly achievable.

Harvisting hydro power at the top of the watershed is prohibited by the cost of transmissin lines. But other means of collection can now be considered.

The basic hydrogen farming process. The slide on the right shows the basic components of the dam less Hydro power system. The site of multiple sites are chosen with your old access and easy plumbing conditions. Intakes and forebays are designed to remove debris on the floor and can be as simple as a pipe of the screen in the pond. Piping to the powerhouse can start as simple as a flexible plastic tube . The closer it is to the powerhouse the stronger it may need to be to the point of which it's made out of steel or reinforced concrete. Powerhouses are simple structures that protects the turbine generator and hydrogen production equipment. A hydrogen storehouse like a common farm milkhouse can perhaps service multiple power houses. Power houses can be stacked or parallel along the stream to provide the maximum amount of power delivery to the a hydrogen storehouse. Combinations and mixtures are virtually infinite allowing for maximization of the harvesting of hydrogen in a given area. Depending on the course of the stream it could be tapped many times during its path from the top of the watershed to the point at which it is harvested.

There is 10 times more power at the top of the watershed than at the bottom where it is now utilized. Environmental impact at the top with micro hydro power stations will be very low.

Here's what the Hydro generators for Hydro farms are going to look like. They come in all sizes and are manufactured all over the world. Their cost is low in comparison to even the smallest of utility Hydro power plants currently in use around the world. Installing them is likely a job for professionals what can be done at a cost perhaps even as little as $5000. Most of these units require little or no maintenance, and likely have a lifetime measured in decades. So it's a pretty wise investment for even an individual let alone for a small community. These Hydro generators produce energy 24 seven so the total amount of power produced by them can be calculated easily and quickly. The power they produce can also be combined with the wind generators that also might be installed at or near the site they. They too can supply the hydrogen generating and storing facilities that we're going to talk about next. A video perfectly describing these hydro power stations is published in our keynote. The video is made by others condensed from a YouTube video called micro hydro about a system for a lodge on an Indian reservation.

Hydrogen generators

The dissociation of water into hydrogen and oxygen is a pretty well-known and well published topic that has been developed by many manufacturers and suppliers the world over. These hydrogen generators only require electricity and water, something that's in great abundance in the areas where we're going to be doing our hydrogen farming. Some specific details are still undefined or optimize for our purposes but can be adjusted for our specific needs as we go. You'll find many manufacturers that offer their hydrogen generators in a wide range of product output sizes. I would think that those,that will develop these farms will likely optimize the size of the generator to the capacity of the hydro electricity produced. The hydrogen that produced by these hydrogen Generators is of course going to be stored in some kind of tank ready to be offloaded to the next available hydrogen truck. Special connection and filling equipment may need to be specified for this task, but are likely available technology now

Lets use an example of how it might work here in Wisconsin USA. The top of the watershed near upper Michigan is about 1000 feet above it's exit into Lake Michigan at Green Bay. On this eastern side of Wisconsin this watershed is only tapped once or twice for Hydro power. In kaukauna Wisconsin a hydro plant run by the city uses a high volume of water at a head of about 15 ft. To service about 15,000 homes. By simple math that volume of water, only a portion of the total of course, could have been harvested at least 50 or 60 times before this site to provide electric service to 500,000 to a million homes. Harvesting The power in Wisconsin would be easy because the course of the stream is accessible by many roads and perhaps even the power grid. As you get closer to the source of the water dear upper Michigan access is less but opportunities are even greater because the slope of the watershed is higher and there are more streams to tap. OK we'll talk more about this later.

These trucks are probably going to be very similar design two trucks used to transport propane. They will be outfitted with special valves fittings controls and features that make Harvesting hydrogen as easy as harvesting milk here in Wisconsin. The interesting thing too is that they could actually be powered by the hydrogen that they are harvesting. Converting a typical gasoline powered engine to burn hydrogen is about as easy as converting it to use propane or even natural gas. There's no sense importing fuels from a different location to provide power for this part of the hydrogen farming task. Moving hydrogen around by truck is likely just as hazardous or perhaps less hazardous then it is to transport other compressed gases like propane or even gasoline.

Hydrogen H2

Hydrogen delivery trucks would tranfer the H2 from the generation site to the ammonia conversion plant

So what are we going to do with the hydrogen.

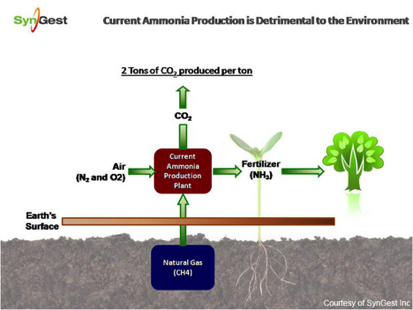

This is the core of the invention, this is what today's technology can do, this is a solution to many problems and a huge economic opportunity to many. You will use the hydrogen to make ammonia. Ammonia is a fertilizer. It is made from lots of hydrogen and a little bit of nitrogen, which is abundant in the air all over the world. The hydrogen used to make ammonia now comes from natural gas. It is a very good fertilizer and it comes at a very high cost both economically and environmentally. For every pound of ammonia produced two pounds of co2 is released into the atmosphere. If we use hydrogen to make ammonia there is no Co2 produced.

For every pound of ammonia produced with natural gas Two pounds of C02 is released into our atmoshere. If you make Ammonia from Hydro-power H2 no C02 is produced

Ammonia production is the second largest user of natural gas and of course it is a billion dollar industry. The demand for ammonia is rising and will continue to rise with the growth in population around the world. The more people we have the more ammonia we need and the more CO2 we will be putting into the atmosphere.Ammonia is one of the most effective ways to fertilize our crops. It's a big player in the game of global warming, producing it from hydrogen emits no co2 , so the more made with hydrogen farming the greater its impact is going to be significant deterrent to global warming. There will be a significant positive economic impact also as hydrogen made ammonia selling at imported methane made ammonia prices will generate millions of dollars in profits shared on a local basis. The local farmers would be more productive and likely benefit greatly too.

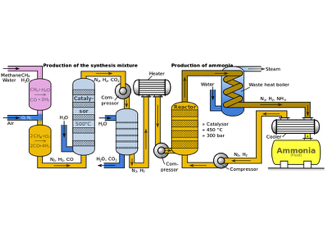

Making ammonia.

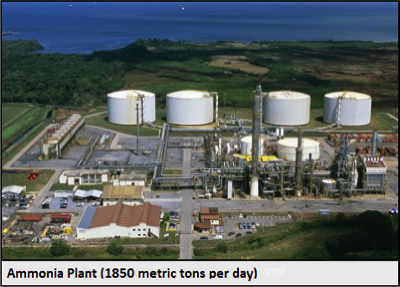

This is a natural gas power plant similar to the ammonia plant on the left

So the way we make ammonia now is with the bosh Haber process. This process is been around for many decades. Producing it has provided wealth to many many large companies and individuals. So it's a proven moneymaker. And what we really need to drive hydrogen farming is money. So this sounds like a good mix it's a good idea. making ammonia from hydrogen is half the process of making it from methane. Perhaps even someday the process could be condensed to the point at which it could be added directly into the hydrogen storage house and ammonia could be delivered directly to the valleys below rather than hydrogen. But for now it would probably need to be produced at a centrally located plant likely at the bottom of the mountain. These plants are likely rather complicated and capital-intensive. However there are many located cross the globe now that could be utilized by early hydrogen farming developers. See a simple video on how to make ammonia.

Ammonia is made from H2 it requires heat and pressure and an Iron catalyst. It is really a simple process that perhaps can be improved with new technology

Researchers have developed a method to produce ammonia simply from air and water. Not only is it more energy efficient than the century-old Haber-Bosch process currently in use all over the world, but it is also greener. It uses some of the same reactants and electricity. It works at lower temperature and pressure also. Perhaps with an abundant source of h2 work will advance to utilize it for greater effectiveness. Perhaps with this process h2 to nh3 conversion plants can be smaller and cheaper.

Ammonia ranks second, to sulfuric acid, as the chemical with the largest tonnage. It is being increasingly made in countries which have low cost sources of natural gas and coal (China and Russia account for ca 40%). The largest plants produce about 3000 tonnes a day and there are plans to build plants that produce 4000-5000 tonnes a day, which would mean that the total world output could be managed with 100 such units. Current production is:

World 140 million tonnes

Europe 16 million tonnes

North America 15 million tonnes

US 8 million tonnes

Asia 74 million tonnes

Russia 12.5 million tonnes1

Middle East 13 million tonnes

That production translates easily to 280

million tons of co2 world wide ...that's a big footprint.

Current production is:

World 140 million tonnes

Europe 16 million tonnes

North America 15 million tonnes

US 8 million tonnes

Asia 74 million tonnes

Russia 12.5 million tonnes1

Middle East 13 million tonnes

Before going for full scale up, a better understanding of the mechanism in this complex multi-electron transfer reaction will be required It is called for now Lichts method and if it works efficiently at low-temperature, and if it can replace the Haber-Bosch process, it would lower the energy input of the production of one of the worlds most important chemicals and lead to a notable reduction in global CO2 emissions.

Explore further: Researchers moving closer to a soluble solution to Haber-Bocsh process

More information: "Ammonia synthesis by N2 and steam electrolysis in molten hydroxide suspensions of nanoscale Fe2O3," by S. Licht et al. Science, www.sciencemag.org/lookup/doi/10.1126/science.1254234

The government and hydrogen farming

If we can expect to grow hydrogen farming as fast as wind farming has in the past decades we would hope that there is plenty of government incentives to do such a thing. Likely the case of hydrogen farming there are many water laws, water rights laws and probably dozens of environmental restrictions on common Hydro developments that need to be addressed. We suggest all hydro farming projects be allowed to continue on on a temporary permit basis and be granted all the economic incentives given to wind farming . In developing countries perhaps the way is paved in gold with no restrictions in place to inhibit the development. In the USA and most well developed countries I would expect that there will be many hurtles to be dealt with as far as permits and allowances.

In developed countries it's very likely that another major issue will be crossing of ownership boundaries. Some rules and guidelines would also likely need to be addressed and provided for situations where watersheds cross areas of multiple owner ships.

From mountain top to farmer fields. Ammonia production from Micro Hydro powered H2 plant can be a great ecconomic and environmental Asset as hydrogen farming succedes

The major improvement offered by the project is the plan, or road map to a place that has likely never been considered before. Likely because it falls outside the realm of standard commercial developmental thinking. There is no industry to drive it , but like wind farming it can easily develop to a huge industry that does a great deal of good for the world and now has direction, roads to follow and produces significant economic benefit. It is ideally suited to developing countries for many reasons. Primary of which is food productions and economic development. Like early wind industry it starts with low cost installations and grass roots,technology that can quickly grow to provide significant improvement to many localities.

The identification of the green chemical is ammonia derived from hydrogen. The improved technology's is the concept of transport of hydrogen rather than electricity from micro hydro plants. The hydrogen is used to make ammonia fertilizer to improve crop production. Ammonia produced from alternative energy producers reduces carbon emissions two times more. Cheep or readily available ammonia provides huge improvements to crop production, which translates to a heathy economy and people. Ammonia produced by hydrogen farming is like best done in developing country's where the need is great and money and resource are in short supply.

Perhaps the greatest opportunity lies in the resemblance to the wind industry. Which started with low wind small machinery ...attracting many manufacturers to proliferate the industry with better and better products for a rapidly growing commerce.In the beginning just like wind developed there would be would be hydro developers..like the wind farm developers...to organize..get permits, plan and finance...there would be land owners ready and willing to invest..time and resources ...major corporate entity to invest and develop projects or components. It will surely grow if promoted and accepted.

Eliminating C02 emission by common production

Page 2 Hydrogen Farming Technology